Now, I have a few posts with ideas an' other bits of wisdom about making bags, but till just now I really didn't have a step-by-step set of instructions for a specific bag, which I imagine might make things more accessible for the first-time bag maker--maybe you.

[Other makin'-stuff posts: DIY Design, Leif Labs: Behind the Scenes.]So here's what the bag looks like, modeled by the ever-handsome Mr Dennis. Enticed? Want your own? Read on.

This is a super-simple messenger bag, a smash-up of Zo Bags and Under the Weather, with a sprinkling of Leif Labs in there. I'm calling it the Zundero.

Zo, outta San Fran, has been making one-piece messenger bags since the 80s. Zo's bags have inspired a smattering of other bag makers and are pretty much only sold on eBay these days to bike-cult geeks.

Under the Weather hails from the Great White North and has been sewing quality bags since the early ohs.

I wanted to offer a bag that was an easy first bag, a tasty entree into the world of bag making, but still held true to the design tenets of Leif Labs: comfortable, sorta-simple, functional, sexy.

And I think it hits the mark on most of 'em.

But I will say this: This bag has one major limitation: it does not respond well to over-filling. The shoulder strap is attached to the back of bag. This allows the flap to close tightly at the top corners of the bag (unlike, say, a Timbuk2 bag), preventing water and other undesirables from getting in there. But this also means the bag can get wonky when you put a big box in there or fill it to the top. There is a solution, though. And that is to make the front of the bag bigger than the back. This involves a slightly more complicated pattern and the addition of compression straps to the lip of the bag to hold its shape when empty. (This pattern is provided after the featured one, though without instructions for the compression straps. Look at a Leif bag to see how it's done.)

Okay, to business...

Materials List

(Read the whole instructions before you buy this stuff--I offer some ideas for other options that you might want to partake in...I think.)

The Shell: 2/3 yard of 1000 denier Cordura nylon. This is what most bagsmiths make their bags out of. Super tough and easy to work with. It usually has a thin polyurethane coating, but despite what people may tell you, this does not make Cordura waterproof. The polyurethane wears off in about a year, and even spankin' new, water will still seep in.

I didn't use Cordura for my bag, though. I used a 9oz marine-grade acrylic-coated polyester that goes by the name Top Gun (no joke). I use this to line my bags, normally...but it's also useful for prototyping bags. And it makes a fine shell, too. It's just not as scuff-resistant as Cordura...but it's a lot more water-resistant.

Liner: 2/3 yards of whatever you want. I didn't line this bag, 'cause we're keeping it simple. But a liner's a good thing to have. Makes it weather-tough and'll add years to its life. As I said before, I use Top Gun polyester, which has a good balance of water repellency and weight. The tried and true is "truck tarp," 14-180z vinyl-coated polyester. It's the heaviest, but most water resistant. There's also TPU, thermal polyurethane. And if you want to go lightweight, nylon packcloth, which also has a thin PU coat. Then there's Hypalon (which T2 once offered for their bags)...but it's pretty pricey. And then, you can just use another layer of Cordura.

1 2" buckle. This is your strap buckle (provided you're using two-inch webbing). I used a side-release buckle for my bag. It makes for easy one-handed adjustment and doesn't eat up the webbing. Use any buckle you want...but make sure to match the webbing to the buckle. Don't use a cam-lock buckle with seatbelt webbing, it's too thin. Don't use soft webbing with a metal buckle...blah, blah...

3 1" buckles. One is for the waist strap. Fastex, aka ITW Nexus, makes the best buckles. Period. You can request free samples at their Web site (www.itwnexus.com).

1 1" tri-glide. This is to make the waist strap removable. If you don't want this as an option, don't get one. Ha.

2.5 yards strap webbing. Any kind of 2" webbing you'd like to get. I like seatbelt webbing, but you can only get it at some places (the junkyard is the best, though). Heavy weave nylon webbing is also a good choice.

2.5 yards 1" webbing. Flat-weave nylon webbing is the best. Steer clear of polyprop webbing. It's not as abrasion resistant and doesn't work as well in buckles.

4 yards grosgrain ribbon, binding tape, bias tape. You need something to cover your seams and the flap edge. Since there aren't any curves in this bag, nylon grosgrain is the best way to go. If you want to make a curved strap, I recommend using type II Mil-W-4088 nylon webbing. It's a lightweight mil-spec webbing with a herringbone weave, which makes it flexible. You can get small amounts from Para Gear (paragear.com).

1 2" Tri-glide. We use one of these to make the shoulder strap removable. Not an absolute necessity, but nice to have.

Thread. Nylon or polyester upholstery thread. The kind you get from your local sewing store will suffice. If you have access to industrial supplies, use N69 or N92, preferably the latter. I use Coats brand.

Two other popular options not featured on my bag:

Velcro. Some people like it. I do not. 39" or so of 2" hook. 20 inches of 1.5" loop. Get the name brand stuff.

Reflectors. Always a good idea, especially if you're riding. You can sew them to your bag or make magic silver tails, as I call them. Ha. Identi-Tape has all kinds, though there are a lot of places where you can get it, maybe your LBS.

Where to Buy Stuff

Unless you're in a larger city or your local outdoor supply store just happens to be awesome, you'll probably have to buy most of your stuff on the Web. Here are some places I've shopped (and some I haven't):

Outdoor Wilderness Fabrics, Inc. (owfinc.com)

They have everything you need...and they're the only place I've found to buy quality foam for shoulder pads in small quantities. They don't have secure online ordering yet, but their sales staff is super nice and helpful. I don't think they have real seatbelt webbing yet, though.

Rockywoods Outdoor Fabrics (www.rockywoods.com)

I've only purchased Cordura from them, which they have a great selection of. Online ordering. They have everything you need for this bag. (They don't have foam, though.)

Para Gear (paragear.com)

I've haven't ordered from these guys yet (I get my mil-spec binding tape from www.dj-associates.com, in bulk), but plan to some time. I'm pretty sure you can get everything you need here. Their Cordura runs on the expensive side, but you can get wacky parachute buckles and lots of mil-spec webbing. Sweet.

Seattle Fabrics (seattlefabrics.com)

I haven't ordered from them before, but they're worth looking at. Sometimes they have things that no one else has. But usually you can find everything else for a bit cheaper. (I don't think they have foam, though. I don't know why it's so hard to get closed-cell foam...)

Perfect Fit (www.perfectfit.com)

They have a wide array of vinyl, if that's what you want for your liner. It's listed under Boat Topping, I think. This is also a good place to get Coats thread.

Rochford Supply (www.rochfordsupply.com)

Another place to get vinyls. They also have Top Gun and other marine fabric. They offer a lot of discount second-quality stuff, too. This is probably the cheapest place to get everything...though, they have a $50 minimum order...

eBay!

There are a lot of little shops on eBay that sell Cordura and buckles and everything else. Poke around.

Sewing Machine

You don't necessarily have to have a sewing machine to make this bag, but it helps.

You should be able to sew most of it on your typical domestic sewing machine (make sure you use the right needle). Though, you might have to hand stitch some of it with a sewing awl, especially the shoulder strap. I have the Awl for All, which I've used to sew bags. Good times.

As far as industrial sewing machines go, needle-feed, walking-foot upholstery machines are where it's at. Maybe you know someone who has one.

The Pattern

Okay, here's what the pattern looks like. If you want to make this bigger or smaller, it's pretty easy to do. The flap width (at the very top) is the bottom length + the bottom width. In this case, 14+7=21. You add 1/2 inch on both sides for a seam allowance to get 22 inches and that's how wide your piece of fabric is.

Hark! This is the alternative pattern I mentioned above. The Zundero II, Super Loader. Ha.

Hark! This is the alternative pattern I mentioned above. The Zundero II, Super Loader. Ha.It's a bit goofy, but very useful. This is a simplified version of the pattern I use for my bags, though it'll perform just as well. Those right triangles are all the same size, if you were wondering.

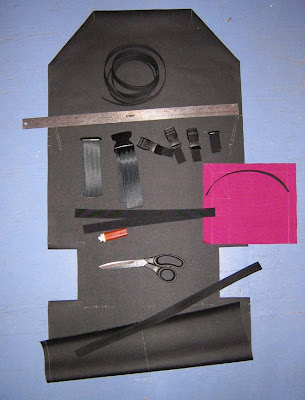

Time to cut!

Time to cut!This is everything except the shoulder strap and waist strap (I didn't know how long to make 'em at the time of this picture).

That pink fabric is for the inside pocket. It's 10.5x9 inches. You should have enough fabric from the shell for the pocket. Usually a yard of fabric is around 60" long.

Time to Sew!

Time to Sew!Makin' the inside pocket.

Cover the top edge with tape. You can always just roll the the top edge, but with this weight of fabric, it's a bit easier just to cover the edge if you're using a lighter sewing machine.

A note on stitch length: Ideally, you want to have a stitch length of about 6-8 stitches per inch. It's okay to have a bit more...just don't go below six.

[If you were wondering, I'm not using nylon grosgrain here. I'm using an acrylic Sunbrella binding tape. I bought a bunch of it and it turned out to stink...so I'm trying to use it up. Ha.]

[For Velcro users: If you're just using one layer of fabric, you need to take into account stitch interference with the inside pocket.]

Once you've finished the top edge, sew around the pocket an inch in from the edge.

Once you've finished the top edge, sew around the pocket an inch in from the edge. Now fold the raw edge in under itself and sew around the pocket again. This makes a clean-looking pocket that doesn't use a lot of binding tape.

Now fold the raw edge in under itself and sew around the pocket again. This makes a clean-looking pocket that doesn't use a lot of binding tape. Sweet. I've added a pen slot there. It's two-inches wide. And the main pocket is 6.5" wide.

Sweet. I've added a pen slot there. It's two-inches wide. And the main pocket is 6.5" wide.[I usually put the pen slot on the left side so it's easier to get to, but I wasn't thinking when I sewed this on. Ha.]

Tapin' the lip.

Tapin' the lip. Waist strap tri-glide.

Waist strap tri-glide. It's located there at the bottom right of the top trapezoid, a 1/2 up from the corner. If you wear your bag on your right shoulder, flip it.

It's located there at the bottom right of the top trapezoid, a 1/2 up from the corner. If you wear your bag on your right shoulder, flip it. One buckle on!

One buckle on! We're sewing the tri-glide buckle onto the shoulder-corner of the bag. This is where the shoulder strap attaches to the bag. I've made this step a bit more complicated to get a better angle for the shoulder strap (I usually attach the strap at forty-five degrees) and to make it super strong. If you want to skip this step, that's fine. The webbing might wrinkle a little at the corner, but it'll work just as well. So just ignore the buckle there and sew the end of your strap to the bag. Note that we're sewing it 1/4" away from the fold line. This allows some sewing room and some folding room when we turn the bag right-side out.

We're sewing the tri-glide buckle onto the shoulder-corner of the bag. This is where the shoulder strap attaches to the bag. I've made this step a bit more complicated to get a better angle for the shoulder strap (I usually attach the strap at forty-five degrees) and to make it super strong. If you want to skip this step, that's fine. The webbing might wrinkle a little at the corner, but it'll work just as well. So just ignore the buckle there and sew the end of your strap to the bag. Note that we're sewing it 1/4" away from the fold line. This allows some sewing room and some folding room when we turn the bag right-side out.With the buckle: With 14" of 2" webbing, finish the ends by folding them under (or with a really thick webbing, melting). Sew 3.5" of webbing to the bag. Slide the buckle onto the webbing as shown. Fold and sew (next step).

Here we've folded the webbing and sewn it to the bag. Again, we've done this because (a) it makes the shoulder strap removable (in case you wear it out or your dog chews it up) and more adjustable; (b) it results in an angle that'll cause the webbing to lie a little flatter 'gainst your back; and (c) it's stronger, as it has a larger area of stitching.

Here we've folded the webbing and sewn it to the bag. Again, we've done this because (a) it makes the shoulder strap removable (in case you wear it out or your dog chews it up) and more adjustable; (b) it results in an angle that'll cause the webbing to lie a little flatter 'gainst your back; and (c) it's stronger, as it has a larger area of stitching. Or you can just sew it on like this. That's about a 55 degree angle between the top and the shoulder strap.

Or you can just sew it on like this. That's about a 55 degree angle between the top and the shoulder strap.

Other shoulder-strap corner. Also 14". This will be on your right side (if you wear your bag on your left shoulder) for easy one-handed adjustment.

Note the two marks on the edge there and inch apart. That's where we're going to put the buckle for the waist belt.

And here we are sewing on the waist strap buckle. 3.5" of webbing.

And here we are sewing on the waist strap buckle. 3.5" of webbing.

It's the box on the top left there.

Finishing the end of the flap straps. This is an important step that I think a lot of bag makers skip. You want at least an inch of fold there. This does a coupla things: One, it prevents your webbing from unraveling. Even if you heat seal an end it can still break and start to fray. And two, it prevents the buckle from falling off the strap, and also makes a little tab for you to grab hold of when the strap is all the way extended.

Finishing the end of the flap straps. This is an important step that I think a lot of bag makers skip. You want at least an inch of fold there. This does a coupla things: One, it prevents your webbing from unraveling. Even if you heat seal an end it can still break and start to fray. And two, it prevents the buckle from falling off the strap, and also makes a little tab for you to grab hold of when the strap is all the way extended. Attaching the flap straps. These are 15.5" each (before finishing the ends). Try to get at least one square inch of stitching on there.

Attaching the flap straps. These are 15.5" each (before finishing the ends). Try to get at least one square inch of stitching on there. These are set 11.5" apart, from their outside edges (so there's 9.5" of space betwixt them).

These are set 11.5" apart, from their outside edges (so there's 9.5" of space betwixt them). And here they are.

And here they are. All right. All the buckles and webbing are on. Time to make it a bag.

All right. All the buckles and webbing are on. Time to make it a bag.[If you're adding any Velcro, reflective material or other pockets, they should be on here, too.]

Sewing the edges together. Fold the lip up to the flap fold line. The inside should be on the outside for this.

I like to sew a basting stitch first. These bags can be pretty unweildly, especially if you don't have a large sewing table. First you focus on getting it together and then getting it straight.

I like to sew a basting stitch first. These bags can be pretty unweildly, especially if you don't have a large sewing table. First you focus on getting it together and then getting it straight.

Now we're going to finish the edge. The grosgrain webbing is going to go from one side seam all away around the flap and onto the other side seam. Beauty.

Reinforcing the waist-strap buckle.

Reinforcing the waist-strap buckle. Now sew the bottom up and tape the raw edges. You probably don't need to finish a rubbery fabric like this, but we're going to do it anyay for quality's sake. You definitely need to do this if you're using Cordura or any other canvas. I don't care if it has a coating on it. In one year it'll be a mess. Not finishing your edges smacks of cheapness and fuckery.

Now sew the bottom up and tape the raw edges. You probably don't need to finish a rubbery fabric like this, but we're going to do it anyay for quality's sake. You definitely need to do this if you're using Cordura or any other canvas. I don't care if it has a coating on it. In one year it'll be a mess. Not finishing your edges smacks of cheapness and fuckery.

Taping the bottom. After this, turn it right-side out.

[Note: I've used a 3/4 inch seam allowance for my bottom. This is what I use on my bags, so I did this out of habbit...but 1/2 is plenty wide. No less, though!]

Sewing on the flap buckles with 4" of webbing. I like to put my buckles at the very edge of the flap. It makes 'em easier to get at, especially if you're wearing gloves. It also makes it easier to buckle 'em one-handed...otherwise that bit of flap can get in the way. And for Christ' sake, don't hide them under the flap.

Sewing on the flap buckles with 4" of webbing. I like to put my buckles at the very edge of the flap. It makes 'em easier to get at, especially if you're wearing gloves. It also makes it easier to buckle 'em one-handed...otherwise that bit of flap can get in the way. And for Christ' sake, don't hide them under the flap. Attaching the shoulder strap to the tri-glide buckle, 50" of webbing. This is called a double-back buckle on climbing harnesses. You feed the webbing through and then back again under the buckle.

Attaching the shoulder strap to the tri-glide buckle, 50" of webbing. This is called a double-back buckle on climbing harnesses. You feed the webbing through and then back again under the buckle.This is a really secure setup, but since seatbelt webbing is so slippery it still tends to creep. If you want it super secure, sew a piece a regular nylon webbing to the seatbelt webbing. That is, if you want to be able to adjust the webbing up top. I don't care about this, so I just finished the end of the webbing and put it up against the buckle. It's not going anywhere.

Shoulder strap buckle. You can put some elastic webbing on the strap here to stick the loose end in. Or you can just tuck it in between you and the strap. Again, finish the end of the webbing by folding it and sewing it. Make a 2" tab here.

Shoulder strap buckle. You can put some elastic webbing on the strap here to stick the loose end in. Or you can just tuck it in between you and the strap. Again, finish the end of the webbing by folding it and sewing it. Make a 2" tab here. So this is what it should look like when you turn it right-side out and attach the webbing. Looks pretty clean.

So this is what it should look like when you turn it right-side out and attach the webbing. Looks pretty clean.

And the back. Attach a 31" piece of webbing for the waist strap. Remember to finish the end, and attach it to the tri-glide buckle like above.

And we're done! Woo woo.

And we're done! Woo woo.Unless you want a shoulder pad...well, that's a whole 'nother chapter. Here's a super-simple one, though: an 18x2.5" 3/8" pad in a fleece sock sewn to the strap. Easy peasy.

Feel free to send me questions...I'm sure I've forgotten to include something in here...

Happy trails.